It is not widely known, but EMS (Electronic Manufacturing Services) companies are playing a key role in helping to create better electronic products today. They do so by providing a range of specialized services that help companies design, manufacture and test electronic products more efficiently, before they can be produced and launched. In this article, we will explain how EMS companies are helping to create better electronic products today.

Design Services

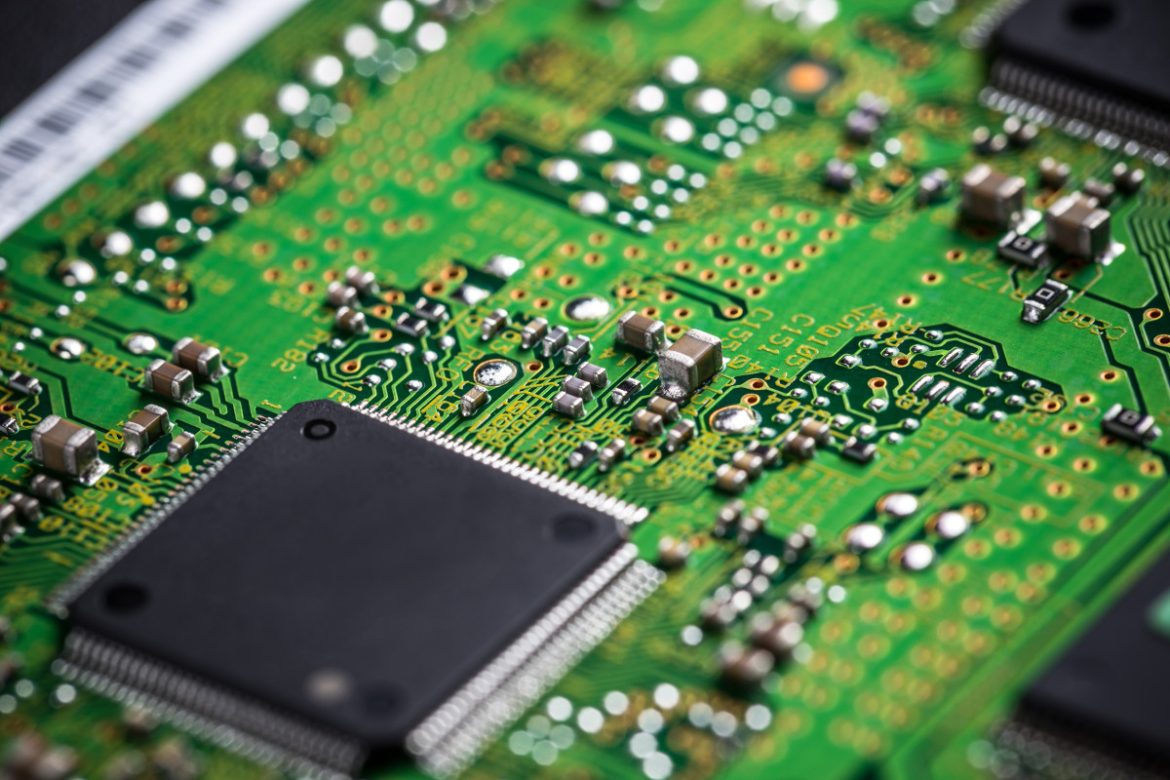

Imagining a product is one thing, turning the idea into an object is a completely different one. That is why many companies that specialize on bringing innovative objects to market call upon EMS to help them in their creations. Inserting the electronic components inside the product is often the most complicated task. That is why EMS companies offer design assistance services, which can help companies develop more efficient and effective electronic products. For example, through SMT assembly, they can create smaller and more complex circuits, which completely changes the product, making it easier to use and more efficient at the same time.

Once the design of the object is completed, they can then move on to the creation of a prototype which will be able to prove that the product works or indicate that there is a need for some changes to be made to it. This is an important part of any product that includes electronic components inside them, and it may require to be done a few times, until the product is considered perfect and ready to be produced.

Test, Validation and Certification

Before an electronic product can be launched in various countries, it will need to go through testing, in order to receive validation and a certification to go along with it. Otherwise, it may not receive approval by authorities and cannot be sold in some regions of the world. An EMS company is also specialized in testing the various products that are in preparation and looking to hit the market. If during these tests it is found that the product doesn’t comply with certain regulations, the EMS provider will be able to work on it, so that it resolves the situation. In this phase, the product will automatically gain in quality and will probably be more secure for users as well, afterwards. This is one of the ways that EMS help create innovative objects that make our world better.

Manufacturing

Whether a company decides to design and test its products in-house or not, they can always call upon the services of an EMS in order to produce them. Having a production line is not necessarily something that designers and creators want to invest in, as this is not the core of their profession. If they chose to do so, they would need many employees and a person that can lead the team. It translates into costs that will be much more important than if they chose to externalize the process by using the services of the EMS. Since the latter group usually have state-of-the-art manufacturing facilities, it means that the electronic product will be produced quickly and efficiently, reducing lead times while ensuring that high-quality products will come out in the end.

Manufacturing a single product is not easy, since there will be times when the output will need to be reduced, while the opposite can also happen, requiring a greater volume of products to come out in a short period of time. In the first case, the company may still have to pay its employees, and in the second, it can be impossible for them to raise the output. That is unless they use an EMS company, since they can scale up or down the production capacity quickly and adapt to changing market demands.